"AN INVESTMENT IN KNOWLEDGE ALWAYS PAYS THE BEST INTEREST" BENJAMIN FRANKLIN

"AN INVESTMENT IN KNOWLEDGE ALWAYS PAYS THE BEST INTEREST" BENJAMIN FRANKLIN

Research Article - (2021) Volume 58, Issue 1

Published: Jun 28, 2021

This paper presents creation and tentatively research the working of Pedal Powered Water Pump (PPWP) alongside its refinement which had utilized for unadulterated drinking water supply and nursery water system. PPWP will comprise of a radiating siphon worked by pedal force. The diffusive siphon is situated on its substitute such a way that determined shaft of the radiating siphon was butted to the bike wheel. By accelerating the bike, the bike wheel pivots, accordingly turning the diffusive siphon which in diverts releases water from the sump. PPWP gives drinking water and water system in far off regions where power isn't accessible. PPWP isn't just liberated from contamination yet in addition give solid exercise. PPWP decreases the rising energy costs. PPWP will plan as a versatile one which can be used for water system in different spots. The exploratory examination was executed and execution of the PPWP had done at various rpm. The outcomes show that the PPWP will give a lot of release and head. The PPWP requires just manual force along these lines decreasing the service bill extensively. Test result shows that release of about 0.0025 m can be acquired for around 140 rpm.

http://www.oajournal.org/

http://www.journalsres.org/

http://www.journalsres.com/

http://www.journalsoa.org/

http://www.journalsoa.com/

http://www.journalsci.org/

http://www.journalres.org/

http://www.journalres.com/

http://www.journaloa.org/

http://www.journalinsights.org/

http://www.jpeerreview.org/

http://www.imedresearch.com/

http://www.imedpubjournals.com/

http://www.imedpubjournal.org/

http://www.imedjournals.org/

http://www.peerreviewedjournal.org/

http://www.peerjournals.org/

http://www.peerjournals.com/

http://www.sciencesinsight.org/

http://www.scholarresearch.com/

http://www.scholarres.org/

http://www.nutritionres.com/

http://www.gastroinsights.org/

http://www.pathologyinsights.org/

http://www.echemistry.org/

http://www.echemcentral.com/

http://www.chemistryres.com/

http://www.biochemresearch.org/

http://www.biochemjournals.com/

http://www.ebusinessjournals.org/

http://www.businessjournals.org/

http://www.peerjournal.org/

http://www.oajournalres.com/

http://www.alliedres.org/

http://www.alliedjournals.org/

http://www.alliedjournal.org/

http://www.scientificres.org/

http://www.scientificres.com/

,

https://www.mongoliannutrition.com/

https://www.nsbmb.com/

https://www.arabspp.org/

https://www.arabianmultidisciplinary.com/

https://www.italystemcell.com/

https://www.traditional-medicine.org/

https://www.episportsmedicine.org/

https://www.worldmedicalassociation.org/

https://www.silaeitaly.com/

https://www.ceramicsmedicine.org/

https://www.isaddictionmedicine.org/

https://www.europeanbionetwork.com/

https://www.aarsecp.com/

https://www.edycseg.org/

https://www.europeanneurology.org/

https://www.clinicaldermepi.com/

https://www.cardiac-society.com/

https://www.psychologicalassociation.org/

https://www.indian-psychology.com/

https://www.mongoliancardiology.org/

https://www.pediatricssociety.com/

https://www.cocrt.org/

https://www.european-aesthetic.com/

https://www.sohnsb.org/

Pedal power, Rpm, Centrifugal pump, Aerofoil, Reverse osmosis.

This report plates the need of the venture and different parts of preparation, plan, and determination of materials, creation, erection, assessment and testing. Pedal Powered Water Pump alongside water purification (PPWPWP) is an eco-agreeable framework (Ganorkar et al., 2014). The PPWPWP works just on mechanical energy without power (Akinwonmi et al., 2001). PPWPWP gives drinking water and water system in far off regions where power is as yet a significant issue alongside giving eco amicable climate it likewise assists with directing a decent wellbeing while at the same time accelerating PPWP isn't just liberated from contamination yet additionally gives sound exercise. PPWPW Produces the rising energy costs (Garg et al., 2013). PPWPWP was planned as a compact one which can be utilized for water system in different spots. PPWPWP comprises of a divergent siphon worked by pedal force (Lee, 2007). The radiating siphon is situated on its substitute such a way that determined shaft of the divergent siphon has butted to the bike wheel. By accelerating the bike, the bike wheel pivots, consequently turning the diffusive siphon which in diverts releases water from the sump and sent to pre channel which cleanse the water at the same time (Islam et al., 2007).

Safe drinking-water and sufficient sterilization administrations to everything is maybe the best advancement disappointment of the 21st century. The most heinous result of this disappointment is the high pace of mortality among small kids from preventable water-related-infections. Water is fundamental to support life, and a good (sufficient, protected and open) supply should be accessible to all. Improving admittance to safe drinking-water can bring about substantial advantage to wellbeing. Almost, one billion individuals endure unnecessarily without admittance to safe drinking water and more than 5,000 kids pass on every day due to water related infections. Water-related sicknesses: brought about by bug vectors, particularly mosquitoes, and those varieties in water; incorporate dengue, filariasis, jungle fever, onchocerciasis, trypanosomiasis and yellow fever. Drinkable water sources are far off from most towns in India.

Ladies and youngsters particularly goes through long periods of work just to meet the essential requirements of their families strolling five miles and more to close towns just to approach drinkable (cleansed) water. Some wealthy occupants in these towns travel significant distances with engine bicycles and trucks which devour fuel and dirty the air.

Additionally, a group of five requirements, at least fifteen gallons of water required every day. The best way to clean the stream water accessible to these towns is by bubbling which additionally burns-through valuable assets and adds to deforestation since the lone wellspring of energy for heating up this much water is kindling and charcoal.

Nonetheless, various investigations from low-pay nations have shown that improved admittance to water and the subsequent expansions in the amount of water or time utilized for cleanliness are the deciding variables of medical advantages, as opposed to enhancements in water quality. The target of this work is to plan a system to be utilized with water channel to supply purged water for towns and distant places by saddling the human pedal force (Khan et al., 2015). Hand worked siphons are broadly utilized in homegrown, mechanical and business applications. The limit of this siphon differs from 5 feet to 50 feet. Higher head siphons are utilized for siphoning savoring water towns.

Working principle

This siphon comprises of one chamber, cylinder two quantities of non-return valve and hand switch. At the point when switch is raised, the cylinder inside the chamber drops down into the chamber causes water is sucked. At the point when the switch is brought down or pushed down, the water inside the chamber released to outlet point. The pedal is pivoted by the foot and thus wrench turns causes the associate bar swayed to the switch of the siphon. Consequently the water is released to the power source by accelerating the cycle pedal.

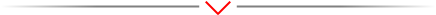

The rundown of material needed for fabricate is set up from the drawing. The rundown is known as "Bill of materials". Accessibility of these materials is overviewed and bought from the market. Next work of preparation is to "select the best strategy" make the item, so the wastage of materials, work, machines and time can be dispensed with by thinking about different techniques (Ahsan-uz-Zaman et al., 2017). The best technique is to be chosen for manufacture and different works. The legitimate strategy and appropriate individual and the motivations behind activity, need activity, appropriate machine arranging. The best strategy is the created and is applied to manufacture the task. While arranging legitimate consideration ought to be set aside to discover the machining effort for the activity as right as could really be expected. So plan of full utilization of machines can be made and the machine stacking system can be chosen. It is hard to fabricate every one of the segments required for the venture in the machine shop (Rao et al., 2014; Subash et al., 2014). For each situation, we ought to conclude whether to make or purchase about a specific thing. It is chosen during the arranging subsequent to making a total investigation of relative benefits and bad marks (Stephen et al., 2015). Results acquired from "activity arranging" and machine stacking help in computing the gear require Specification of the hardware ought to be set somewhere around thinking about then drawings. Drawings will likewise help in choosing the important necessity of apparatuses and frill. A seat is spot to sit, frequently alluding to the space one sits upon instead of different components like armrests. Seat is a course of action in any bike on which an individual can sit easily in guest plan the plan factor is consistently consider as indicated by their utilization in any vehicle. Seat might be made of plastic, elastic, metal and so on material Fig 1. In some guest plan suspension is additionally consider suspension could be spring or it very well might be food.

Figure 1: Seat arrangement and suspension spring

Pedal arrangement

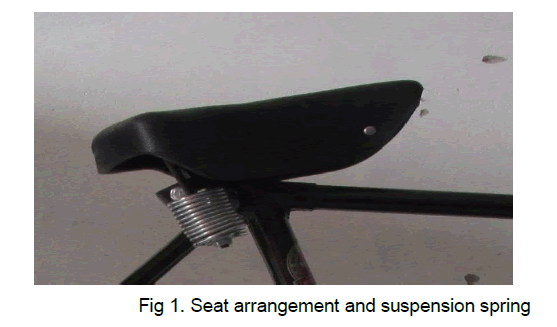

A bike pedal is the piece of a bike that the rider pushes with their foot to impel the bike. It gives the association between the cyclist's foot or shoe and the wrench permitting the leg to turn the base section shaft and move the bike's wheels. Pedals as a rule comprise of an axle that strings into the finish of the wrench and a body, on which the footstools or is connected, that is allowed to pivot on course concerning the shaft Fig 2.

Figure 2: Pedal arrangement and shifting mechanism

Pedals were at first joined to wrenches associating straightforwardly to the determined (normally front) wheel. The wellbeing bike, as it is known today, appeared when the pedals were appended to a wrench driving a sprocket that communicated capacity to the determined wheel through a roller chain.

Gear

Bike outfitting is the part of bike drive train that decides the connection between the rhythm, the rate at which the rider pedals, and the rate at which the drive wheel turns. On certain bikes, there is just stuff and the stuff proportion is fixed. Numerous contemporary bikes have different pinion wheels and along these lines various stuff proportions. A changing instrument permits determination of the fitting gear proportion for proficiency or solace under the common conditions: for instance, it could be agreeable to utilize a high stuff when cycling downhill, a medium stuff when cycling on a level street, and a low stuff when cycling uphill. Diverse stuff proportions and stuff ranges are suitable for various individuals and styles of cycling. A cyclist's legs produce power ideally inside a limited accelerating speed reach, or rhythm. Outfitting is enhanced to utilize this limited reach as best as could be expected. As in different sorts of transmissions, the stuff proportion is firmly identified with the mechanical benefit of the drive train of the bike. On single-speed bikes and multi-speed bikes utilizing derailleur gears, the stuff proportion relies upon the proportion of the quantity of teeth on the chain ring to the quantity of teeth on the back sprocket (pinion). For bikes outfitted with center pinion wheels, the stuff proportion additionally relies upon the inward planetary cog wheels inside the center point. For a shaft-driven bike the stuff proportion relies upon the angle gears utilized at each finish of the shaft. For a bike to go at a similar speed, utilizing a lower gear (bigger mechanical benefit) requires the rider to pedal at a quicker rhythm, yet with less power. Then again, a higher stuff (more modest mechanical benefit) gives a higher speed to a given rhythm, however requires the rider to apply more noteworthy power. Various cyclists may have various inclinations for rhythm and accelerating power. Drawn out effort of an excess of power in too high stuff at too low a rhythm can expand the opportunity of knee damage; cadence over 100 rpm turns out to be less viable after short explodes, as during a run.

Bearing

The expression "bearing" is gotten from the action word "to bear" a direction being a machine component that permits one section to bear (i.e., to help) another. The most straightforward orientation are bearing surfaces, cut or shaped into a section, with fluctuating levels of power over the structure, size, harshness and area of the surface. Different orientation is discrete gadgets introduced into a machine or machine part. The most complex course for the most requesting applications is exact gadgets; their production requires probably the best expectations of current innovation Fig 3.

Figure 3: Bearing F205

Chain and sprocket

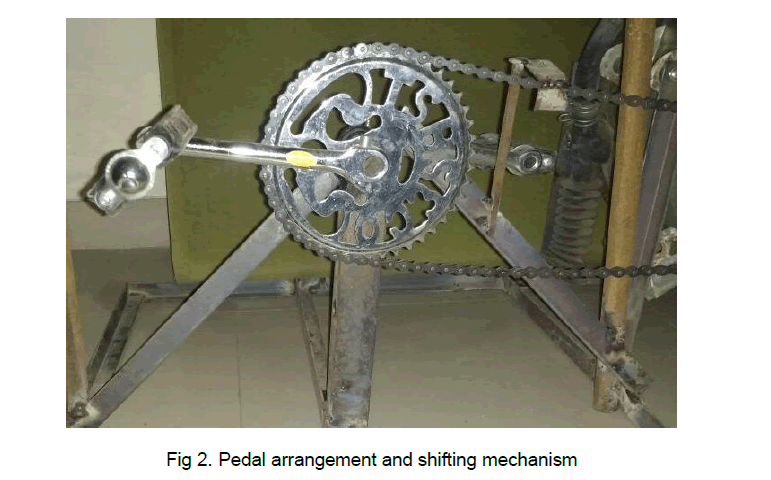

While making your own human fueled vehicles, a chain drive will probably be your picked power move framework, as it is a modest, simple to-introduce and exceptionally effective drive system. Bike chains are genuinely basic, requiring just a single economical apparatus to eliminate and join joins. Since a supine cycle will frequently require a chain that is one and a half to multiple times the length of a normal upstanding bike chain, a few rudiments ought to be known, as you will most likely have to make the chain for your vehicle Fig 4.

Figure 4: Two different sizes of bicycle chain

There are two fundamental sorts of bike chain: single speed chain and multi-speed chain. Single speed chain is for the most part utilized on children's bicycles, BMX bicycles, liner brake cruisers, and weighty payload bicycles. Multi-speed chain is utilized on standard speed bicycles and trail blazing bicycles that require the utilization of a front and back derailleur to switch gears. The two kinds of bike chain have a pitch of 1/2 inch (ANSI standard #40). This estimation shows the length of the connections. Albeit each kind of bike chain and freewheel have a 1/2 in pitch, the width of chain differs a lot, from 3/32"to1/8".

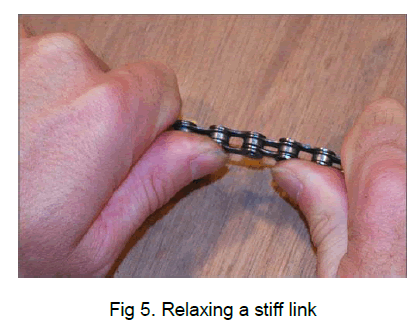

Subsequent to squeezing a connection back into a chain, the pin will have constrained the plates together, causing a firm connection. This hardened connection will cause a skip or bounce each time it goes through the back derailleur, and should be fixed before use. A hardened connection will consistently be made when first joining a chain however it can undoubtedly be loose.

To fix a hardened connection, hold the chain so you can work the connections side to side as demonstrated in Fig 5. Press your thumbs against the plates on each side of the hardened connection and power it to and fro until it no longer sticks when you twist the chain. When the connection has been loose, it will behave like each and every connection without causing the issue.

Figure 5: Relaxing a stiff link

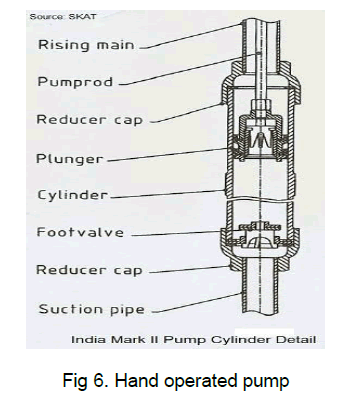

Hand operated pump

Hand worked siphons are broadly utilized in homegrown, mechanical and business applications. The limit of this siphon shifts from 5 feet to 50 feet. Higher head siphons are utilized for siphoning savoring water towns. The Mark II is a shut chamber siphon. The chamber metal fixed cast iron with the foot valve and cylinder congregations made of metal. The cylinder seals are twofold nitrile elastic cup seals. As you can find in the Fig 6, the top and lower part of the cylinder chamber is "covered" with strung reducers. The measurement of the siphon chamber is bigger than the distance across of the riser primary to which it is connected.

Figure 6: Hand operated pump

Upkeep on any piece of the siphon chamber necessitates that the riser primary and the siphon bar be eliminated starting from the earliest stage. The siphon bar is aroused steel and areas are strung together. The siphon chamber is strung onto the last part of riser primary and is eliminated completely as the last segment to emerge starting from the earliest stage. The siphon chamber would then be able to be unscrewed from the riser fundamental. The top and base covers can be unscrewed from the chamber body to access the foot valve, the cylinder valve, the cylinder seals and whatever else inside the chamber body. The Mark II water hand siphons are solid and generally utilized. Nonetheless, for establishment and support, devices and abilities are required that may not be accessible at the town level. Thusly, the Mark II isn't viewed as a VLOM siphon. It ordinarily requires a prepared region professional to introduce and keep a Mark II siphon. The Mark II hand siphon comprises of the over the ground instrument which incorporates the siphon head, siphon handle, water tank, and siphon stand congregations. The subterranean instrument incorporates the riser fundamental, siphon poles and siphon chamber get together. The over the ground instrument is developed of welded steel plate for strength and is hot-plunge aroused for consumption obstruction. These parts might be privately produced. A chain and quadrant instrument of the siphon handle gives simple and exact arrangement of the interfacing bar (see outline). The siphon handle enjoys a high mechanical benefit. It is hefty and is intended to offset the heaviness of the interfacing bars to decrease the siphoning exertion needed from the client. The handle turn get together (fixed metal balls on a hardened steel pivot) makes activity simpler and brings down support needs.

The siphon poles are made of cold drawn splendid steel bar with strung end couplers, electro-excited against erosion. Treated steel bars are additionally accessible. The siphon chamber is produced using a cast iron packaging with a cleaned metal liner and firearm metal unclogger and check valve parts. Seals (siphon cans, valve seals and cap seals) are accessible in naturally safe Nitrile elastic. This siphon can be effectively adjusted for shallow well, windmills and mechanized activities with minor changes.

Types of centrifugal pumps

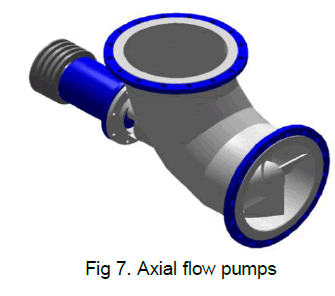

Axial flow pumps: Hub stream siphons contrast from spiral stream in that the liquid enters and exits along a similar course corresponding to the turning shaft. The liquid isn't sped up however rather "lifted" by the activity of the impeller. They might be compared to a propeller turning in a length of cylinder. Pivotal stream siphons work at much lower pressures and higher stream rates than outspread stream siphons Fig 7.

Figure 7: Axial flow pumps

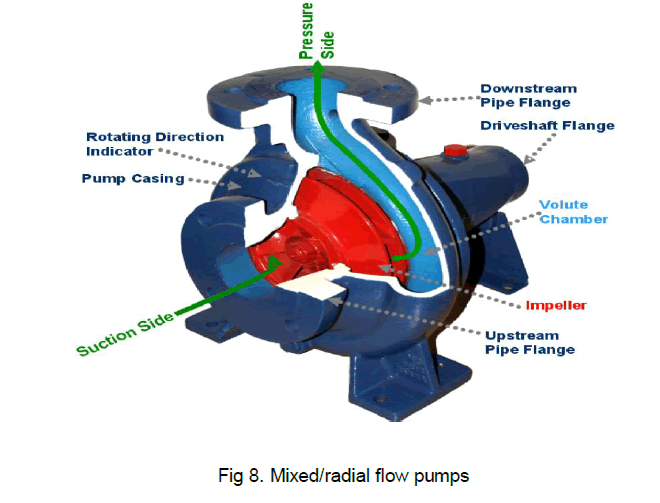

Mixed/radial flow pumps: These pumps are regularly basically alluded to as radial siphons. The liquid enters along the pivotal plane, is sped up by the impeller and ways out at right points to the shaft (radially). Spiral stream siphons work at higher pressing factors and lower stream rates than hub and blended stream siphons. Blended stream siphons work as a tradeoff among outspread and pivotal stream siphons. The liquid encounters both spiral speed increase and lift and leaves the impeller somewhere close to 0 and 90 degrees from the hub course. As a result blended stream siphons work at higher pressing factors than pivotal stream siphons while conveying higher releases than outspread stream siphons. The leave point of the stream directs the pressing factor head-release trademark comparable to spiral and blended stream Fig 8.

Figure 8: Mixed/radial flow pumps

Application of Bernoulli’s principle

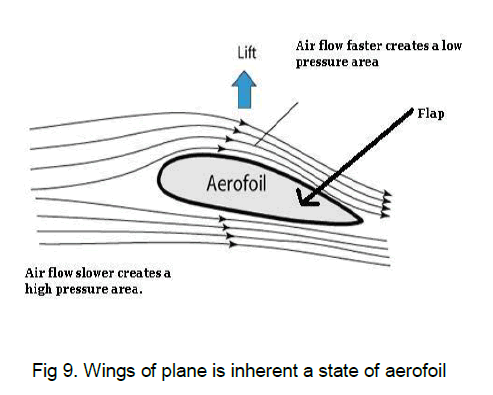

Aerofoil: Wings of plane is inherent a state of aero foil. For a plane to take off it needs to make a vertical power. The wings of an airplane are planned in a state of aerosol to empower the lift to be made. At the point when a plane moves down the runway with speeding up, the wing fold is pointing downwards. This will make an immense lifting power upwards and the plane will take off (Fig 9). At the point when a wing as an aero foil moves in air, the progression of air over the top voyages quicker and makes a locale of low pressing factor. The progression of air beneath the wing is slower bringing about an area of higher pressing factor. The distinction between the pressing factors at the top and underside of the wing causes a net vertical power, called lift, which assists the plane with taking off.

Figure 9: Wings of plane is inherent a state of aerofoil

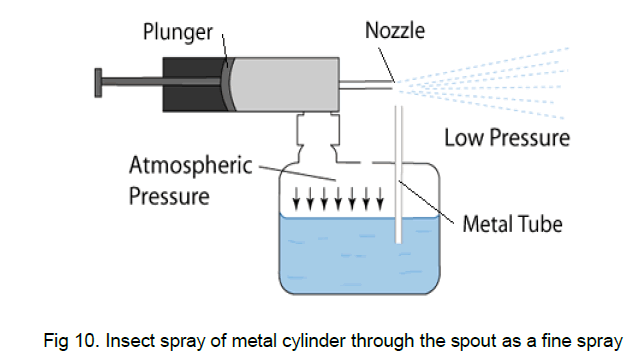

Insect spray: At the point when the unclogger is pushed in, the wind streams at a high speed through a spout. The progression of air at high speed makes a locale of low pressing factor over the metal cylinder. The higher pressing factor of the environmental air follows up on the outside of the fluid bug spray making it ascend the metal cylinder. The bug spray leaves the highest point of the metal cylinder through the spout as a fine spray as show in Fig 10.

Figure 10: Insect spray of metal cylinder through the spout as a fine spray

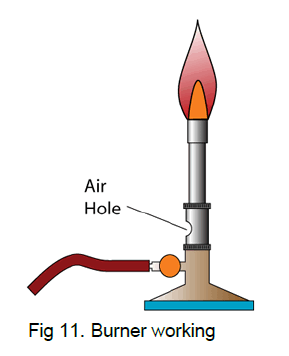

How bunsen burner works: The gas fuel is provided to the Bunsen burner through the gas channel. The speed of the gas is high. It makes a low-pressure region. This makes the air race into the burner through the air opening. This combination of air and gases ascends to the launch of the chimney stack where it is scorched. The combination of gas and air empowers the gas to consume totally to deliver a spotless, hot, and smokeless fire as shown in Fig 11.

Figure 11: Burner working

In working model of “pedal controlled water siphoning and cleaning" we are offering capacity to the shaft which is associated with the siphon. The siphon is then associated with the purifier which all the while filtering the water. Force which we are getting from accelerating is communicated from front to uncommon sprocket through chain drive instrument, a similar rpm then, at that point sent to the pulley which is mounted on a similar shaft. This pulley communicated capacity to the principle shaft through belt drive plan which is then associated with the siphon. This current siphon's outlet is associated with the channel to decontaminate the water The exploratory examination was execute and execution of the pedal fueled water siphoning and purging had done at various rpm.

The different kinds of siphons are utilized for siphoning the water from a sump to tank. This is additionally one of the hand worked siphon which is currently worked through the cycle pedal .The activity and component of this unit and its capacity have been contemplated. At the end, the machine is assembled.

This machine is more benefits of different kinds of hand siphon since it has simpler to work happy with guest plan and great exercise to our body and furthermore less time utilization, simple taking care of and so forth in Table 1.

| S.no | Component | Specification |

|---|---|---|

| 1. | Diameter of sprocket | .168 m (driven ) |

| 2. | Diameter of sprocket | 0.065 m (driver ) |

| 3. | Center distance between | 0.48 m (driver and driven) |

| 4. | No. of teeth in driver | 45 |

| 5. | No. of teeth on driven | 18 |

| 6. | Casing diameter | 0.15 |

| 7. | Discharge diameter | 0.02 m |

| 8. | Suction diameter | 0.025 m |

| 9. | Datum height | 0.9 m |

| 10. | Delivery head | 1.03 m |

| 11. | Suction length | 1.1 m |

| 12. | Delivery length | 2 m 430(N2) 130(N1) (With Load) |

| 13. | Rotating speed | 680(N2) 150(N1) {no load} |

| 14. | Total distance | 0.86 m |

| 15. | Shaft to pump | 0.77 m |

| 16. | Diameter of small | 0.26 m |

| pulley(1) | ||

| 17. | Diameter of small pulley (2) | 0.12 m |

| 18. | Crank radius | 0.18 m |

Table 1. Specification of components

Model calculation

L1=π (r1 + r2 ) + 2 x +(r1 –r2)2 /48

= π (8.2+ 3.2) + 2 * 48 + (8.2-3.2)2/48 L1=1.32 m

We realize that power is as yet one of the serious issue in rustic region. In mid year days individuals battles with the lack of water. pedal fueled water siphoning and sanitization meet these issue as this framework just deals with pedal controlled there is no need of power neither to siphon nor to purge the messy water. of Pedal Powered Water Pump alongside its decontamination which is utilized for unadulterated drinking water supply and water system in far off regions. pedal controlled water siphoning and refinement isn't just liberated from contamination yet additionally give solid exercise. pedal fueled water siphoning and cleaning decreases the rising energy costs. Pedal fueled water siphoning and cleaning is plan as a versatile one which can be use for water system in different spots. The exploratory examination was execute and execution of the pedal fueled water siphoning and purging had done at various rpm. So in this paper we have recommended that the pedal controlled water siphoning and cleaning will give a lot of release and head.